The Mathison family homesteaded 160 acres in 1893 on Stemilt Hill near the town of Wenatchee, Washington. The family’s deed to the land would remain in place as long as they were farming it. Initially, they ran a subsistence farm that produced staples for the family and enough wheat to sell to sustain a living. First generation farmer Thomas Cyle Mathison became a founding partner of the Stemilt Creek Irrigation Company, helping to bring water to his land, which ultimately set the stage for the family’s first orchards.

Stemilt History

Journey through 100+ years to learn the key moments of Stemilt’s rich history.

100 Years of Family Farming and Innovation

1893: Our Homestead Roots

1914: First Orchard Plantings

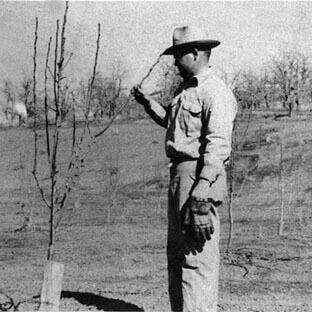

With its rolling hills and fertile soils, Stemilt Hill reminded Thomas of his homeland, Scotland. The locale’s mild desert climate, snowy winters, and plentiful water supply would be the ideal place to grow fruit, so Thomas planted the family’s first 10 acres of apples, pears and cherries in 1914.

1926: The Second Generation

Thomas’ son, Chris Mathison, took over the family farm and gradually expanded the business with new plantings. He was also raising a family with his wife, A.J. In June 1926, A.J. gave birth to twins, Helen and Thomas Kyle, known as TK or Tom. Tom grew up going to school, playing football and working on the family orchard.

1947: Young Tom Leads The Farm

After serving in World War II, Tom returned home to resume work on the family farm. Shortly after, his father Chris died tragically in a farming accident, and Tom was left to lead the farm. Over the next decade, the family struggled to keep the farm going. Tom married Lorraine Goldy in 1950 and the couple quickly started a family, with Bob born in 1951, Kyle in 1952 and Lavonne in 1953.

1958: The Cherry Crop Disaster

The family’s real challenge struck during the 1958 crop year. That year, Tom returned a mere $88 on his 100-ton cherry crop. This crop disaster was a turning point for Tom. If it weren’t for his wife’s business of selling eggs and cream and painting houses, the family would have been forced to sell the orchards. Lorraine laid it out clearly stating: “Tommy, you figure out what is wrong and fix it, or go get a job to support this family.” Tom chose to fix the problem.

1959: Time for a Change

In 1959, Tom followed his cherries to the East Coast and saw how poorly they perished after the long journey. The railcars packed with ice could not sustain the length of the journey, leaving most of the cherries ruined. The following year, Tom traveled to California to study how Italian families harvested cherries and returned home with knowledge and drive to transform his farming practices.

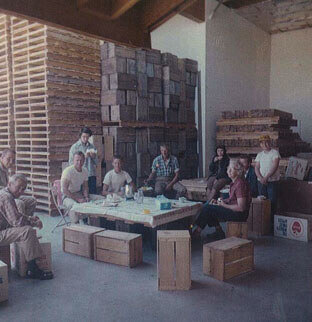

1964: Stemilt Growers is Founded

Tom began packing his own cherries in a small-scale facility that he constructed. After his first year as a grower-packer Tom followed his cherries to the same market on the East Coast where they sold for $40 for a 20 lb. box. A huge turnaround! The following year, several neighbors asked Tom to pack their cherries, and in 1964, Tom founded a fruit-packing business called Stemilt Growers.

1975: Tom Builds Olds Station Facility

Success in the 1960s led to continued expansion, and in 1975, Tom built an apple, pear and cherry packing and storage facility at Olds Station in Wenatchee. Tom’s sons, Bob and Kyle, became involved in the farming side of the business, while Tom managed packing operations and traveled the world to promote the Stemilt brand.

1982: Tom Stickers Fruit

Tom believed people should know who grew their fruit and named Stemilt on that notion. With this belief, Tom became the first to place stickers on apples. The stickers used had Stemilt’s logo on them. Years later, price look-up (PLU) stickers became the norm and are still used today.

1989: Sustainability, Organics, and Cherries in Bags

Always ahead of his time, Tom launched the Responsible Choice® program in 1989 and became an early adopter of sustainability. Tom introduced integrated pest management techniques to orchards to reduce pesticide use, and converted Stemilt’s first apple orchards to organic production. He added a ladybug (a beneficial insect to orchardists) to the Stemilt logo to show the company’s commitment to the environment. Also in 1989, Tom inspired a new way to sell cherries at grocery stores – in bags! Cherries were sold bulk, but Tom believed packaging cherries in bags could help get more fruit into shoppers’ hands. He became the first to put cherries in bags, borrowing technology from the candy world!

2005: Tom Transfers Presidency to Grandson West

Through years of persistence and hard work, Tom helped Stemilt grow from the ground up—literally. In 2005, at the age of 79, Tom passed on the company to his grandson, West Mathison (Kyle’s oldest son). West grew up working in the orchards and held numerous roles at Stemilt before becoming president.

2008: Piñata® Brand Apple Introduced

New apple varieties are arriving to the U.S., and West brings a new apple with heirloom parentage into Stemilt’s apple mix. Piñata® is Stemilt’s first trademarked apple and was introduced to grocery stores in 2008. Since then, Stemilt has successfully introduced more signature fruits, including: SweeTango® apples, Rave® apples, and Skylar Rae® cherries.

2013: Stemilt Clinics Introduced

In 2013, Stemilt opened doors to an on-site health clinic for Stemilt team members. This addition led to the opening of the on-site Stemilt Family Clinic and pharmacy in 2015, which is available to all Stemilt team members and their spouses and dependents for free. Stemilt expanded clinic locations again in 2018 to on-site clinics near its key orchards.

2017: Rave® Apple Launched

2018: The Fresh Cube Comes Alive

Stemilt opens a state-of-the-art automated distribution center called the Fresh Cube. The new facility handles all activities post-packing for apples, pears, and cherries. It also houses Stemilt’s pear ripening center.

2021: Full EFI Certification